Design Engineering – a Solid Footing for Manufacturing

Our core capabilities lie in the design of tools and molds as well as fixtures and gauges. Our highly-experienced designers deploy state of the art technology to implement customer requirements effectively and flexibly.

Our strength lies in the use of innovative tooling and mold concepts for effective and rational manufacturing. We rise to the challenge, think out of the box and come up with innovative and completely new ideas and approaches.

Our shops are equipped with the latest CAD, CAM and simulation programs. We always develop optimum solutions for every possible technical challenge in tooling, moldmaking or part design – even when time is of the essence.

We have extensive experience, especially in overmolding metal parts (insert and outsert technology) and fabrics, as well as with multi-component applications.

Our complete design portfolio covers:

- Part engineering and designs of plastic parts, metal parts, overmolded parts (insert / outsert) or entire assemblies.

- Tool designs for injection molds, stamping and forming tools

- Special processes such as multi-component technology, hard-soft combinations, 2C parts and many more

- Development of gauge concepts, measuring and testing fixtures, as well as other general fixtures and gauges

EXPERTISE AND RELIABILITY

Benefit from our experience.

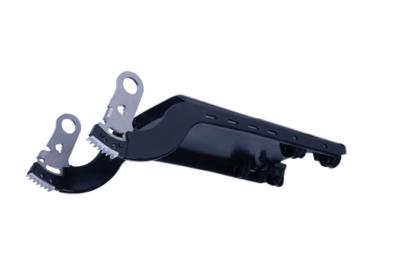

Component for center armrest

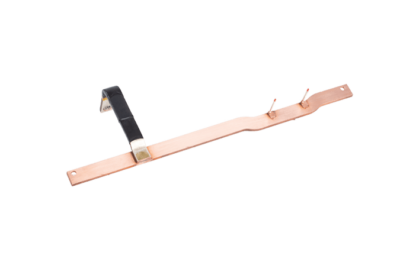

Busbar

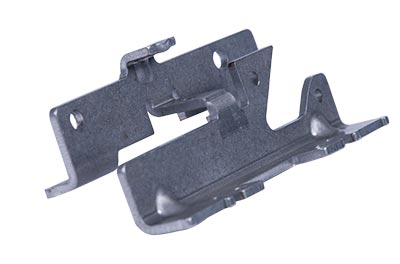

Flap

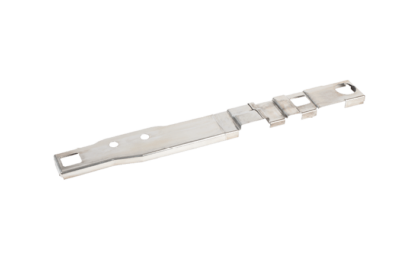

Guiding Rail

Guide

Fixation

Battery cell holder

Overmolded PCB

Charging plug

Overmolded stamped bent part

Assembly overmolded

Roof front assembly

Round bar with springs, overmolded

Overmolded stamped bent part

Roof slider

Cable with pin and lug

Deep-drawn part, shielding

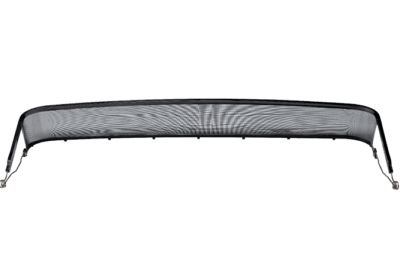

Wind deflector, overmolded fabric

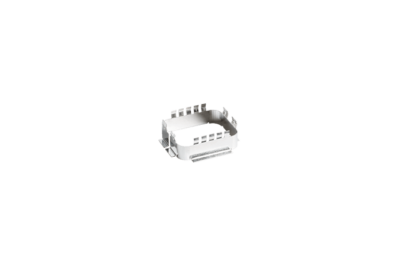

Shielding of plug

Bent spring, overmolded

Shielding of flexible busbars

Medical device

Cap, medical technology