Complexity is our Business

We focus on prototype and small series parts that are close to series design and ready for testing. These are often very demanding with extremely short lead times. If the original materials of the later series parts are required or if the parts have to pass sophisticated test procedures, we mainly work with tools and molds produced by means of rapid tooling or rapid molding.

Although we specialize in complex assemblies with a high level of value added and involving equally high assembly and coordination efforts, we are happy to supply individual parts.

Metal, fabric, plastic – it’s all the same to us.

Stamping, bending, forming, injection molding … – everything is possible.

We organize the entire manufacturing process, from the optimization of the part designs for production to delivery of the measured parts. We take care of the necessary tools and fixtures, procure the necessary materials, manufacture the parts including all coating, welding, gluing work, inserting fasteners, assembly, overmolding, measuring…

As an engineering service provider, we maintain constant pro-active contact with our customers, provide them with information on the progress of their project, and coordinate frictionless processing right up to delivery.

Crucial at the end of each project: The transfer of knowledge to the series supplier. Promptly and easily. The following are typical development projects completed in our company:

- Roof systems, sliding roofs

- High-voltage plugboards

- Plug connector systems

- Charging plugs

- Seats

- Center consoles

- Door or tailgate locks

- Filters

EXPERTISE AND RELIABILITY

Benefit from our experience.

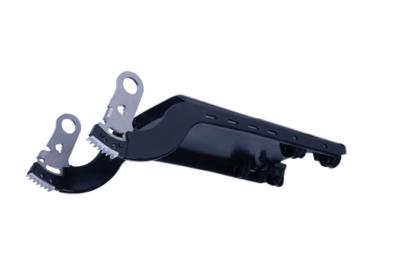

Component for center armrest

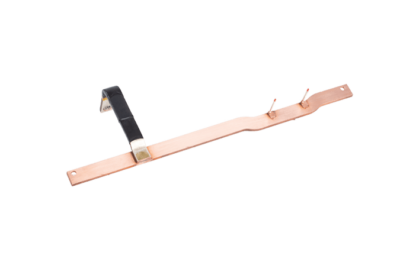

Busbar

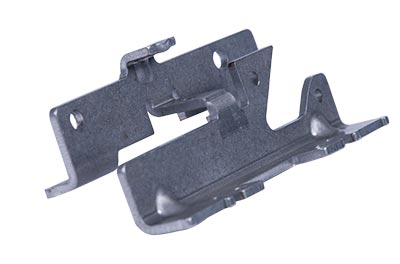

Flap

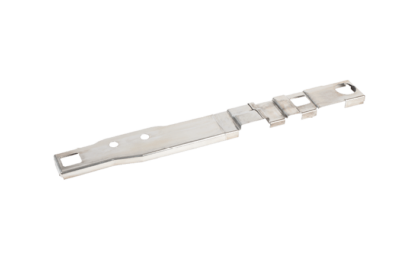

Guiding Rail

Guide

Fixation

Battery cell holder

Overmolded PCB

Charging plug

Overmolded stamped bent part

Assembly overmolded

Roof front assembly

Round bar with springs, overmolded

Overmolded stamped bent part

Roof slider

Cable with pin and lug

Deep-drawn part, shielding

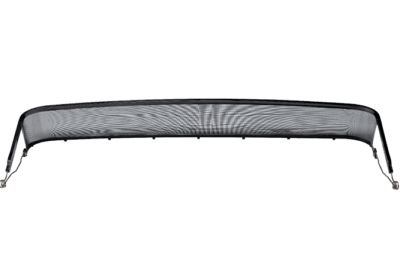

Wind deflector, overmolded fabric

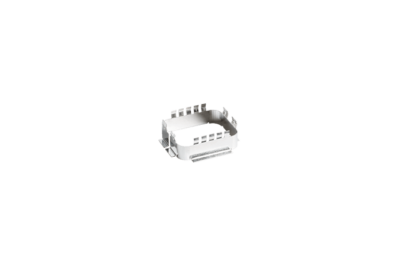

Shielding of plug

Bent spring, overmolded

Shielding of flexible busbars

Medical device

Cap, medical technology