High Performance with Short Lead Times

The profound engineering expertise we have accumulated over the years – working with millimeter-sized parts through to the most complex plastic parts, including large, distortion-sensitive parts – enables us to meet customer demand swiftly, effectively and at competitive prices.

With the support of our highly qualified design engineers, our in-house tooling shop manufactures a large variety of prototype, small-series and volume-series tools, dies and molds, mainly for our own production, but also frequently to customer order.

Very often, when we are involved in prototype and development projects, we deliver tools and fixtures to the later volume series supplier, making sure that the experience gained during the development is carried over to volume production.

We ensure safe and reliable production runs and optimal manufacturing results by means of thorough analyses of the parts before the corresponding tools are produced. We have extensive experience in mold filling analyses, parts distortion, sink marks, flow lines, surface imperfections and air inclusions. This means we achieve the highest level of certainty for our customers even before the first chip falls.

Our tooling expertise extends from aluminum molding tools produced by rapid tooling or rapid molding through to complex tools for series production.

We make use of our own resources and are supported by a worldwide network of suppliers.

Measuring, testing and assembly fixtures, accompanied by the necessary documentation, round off our portfolio.

EXPERTISE AND RELIABILITY

Benefit from our experience.

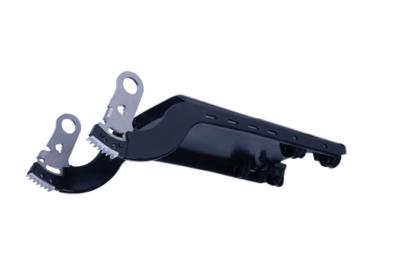

Component for center armrest

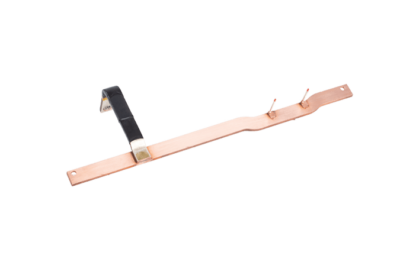

Busbar

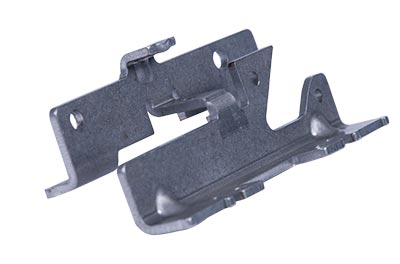

Flap

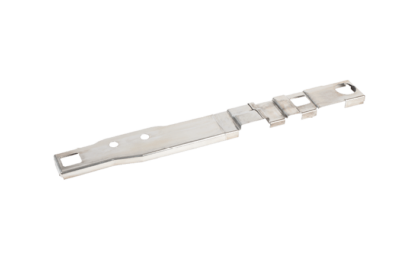

Guiding Rail

Guide

Fixation

Battery cell holder

Overmolded PCB

Charging plug

Overmolded stamped bent part

Assembly overmolded

Roof front assembly

Round bar with springs, overmolded

Overmolded stamped bent part

Roof slider

Cable with pin and lug

Deep-drawn part, shielding

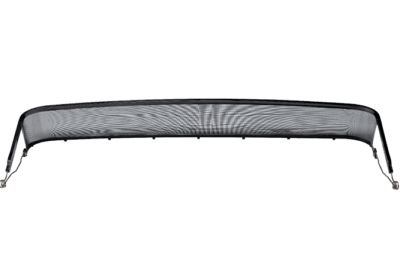

Wind deflector, overmolded fabric

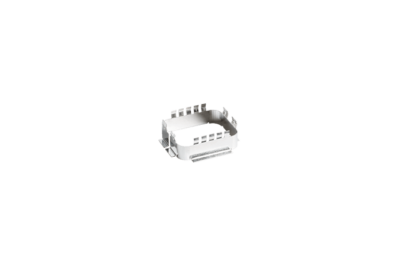

Shielding of plug

Bent spring, overmolded

Shielding of flexible busbars

Medical device

Cap, medical technology